what is slack wax?

Slack wax is a crude, semi-refined wax that is produced as a byproduct during the petroleum refining process. It is called "slack" because it has a lower melting point and is softer than other waxes. Slack wax typically has a yellowish color and is composed of a mixture of hydrocarbons, including paraffin, microcrystalline, and some oil.

Slack wax can be further processed to produce fully refined waxes with specific melting points and properties that are used in various applications such as candles, packaging, coatings, and cosmetics. Slack wax is also used in the production of polishes, inks, and other industrial products.

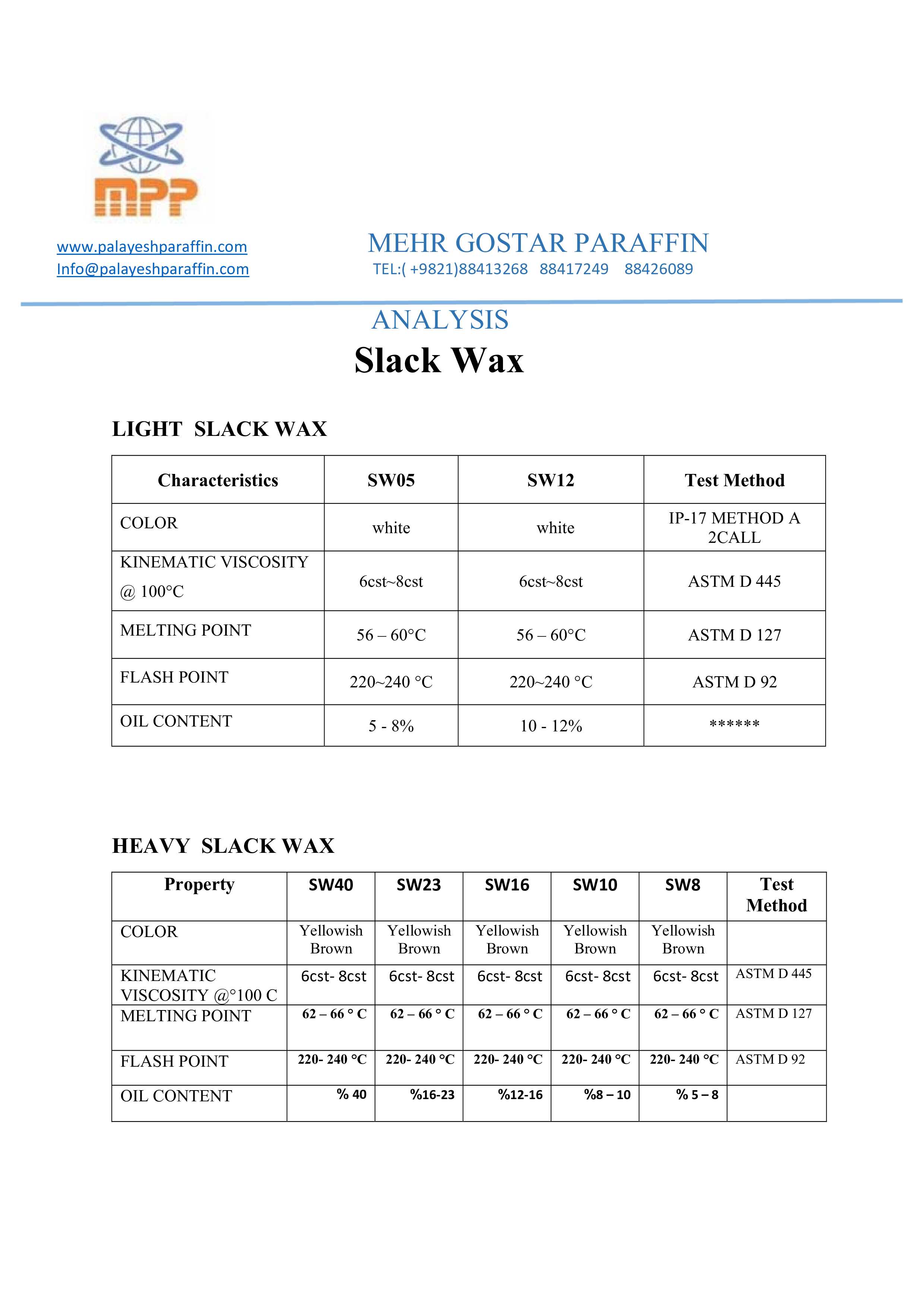

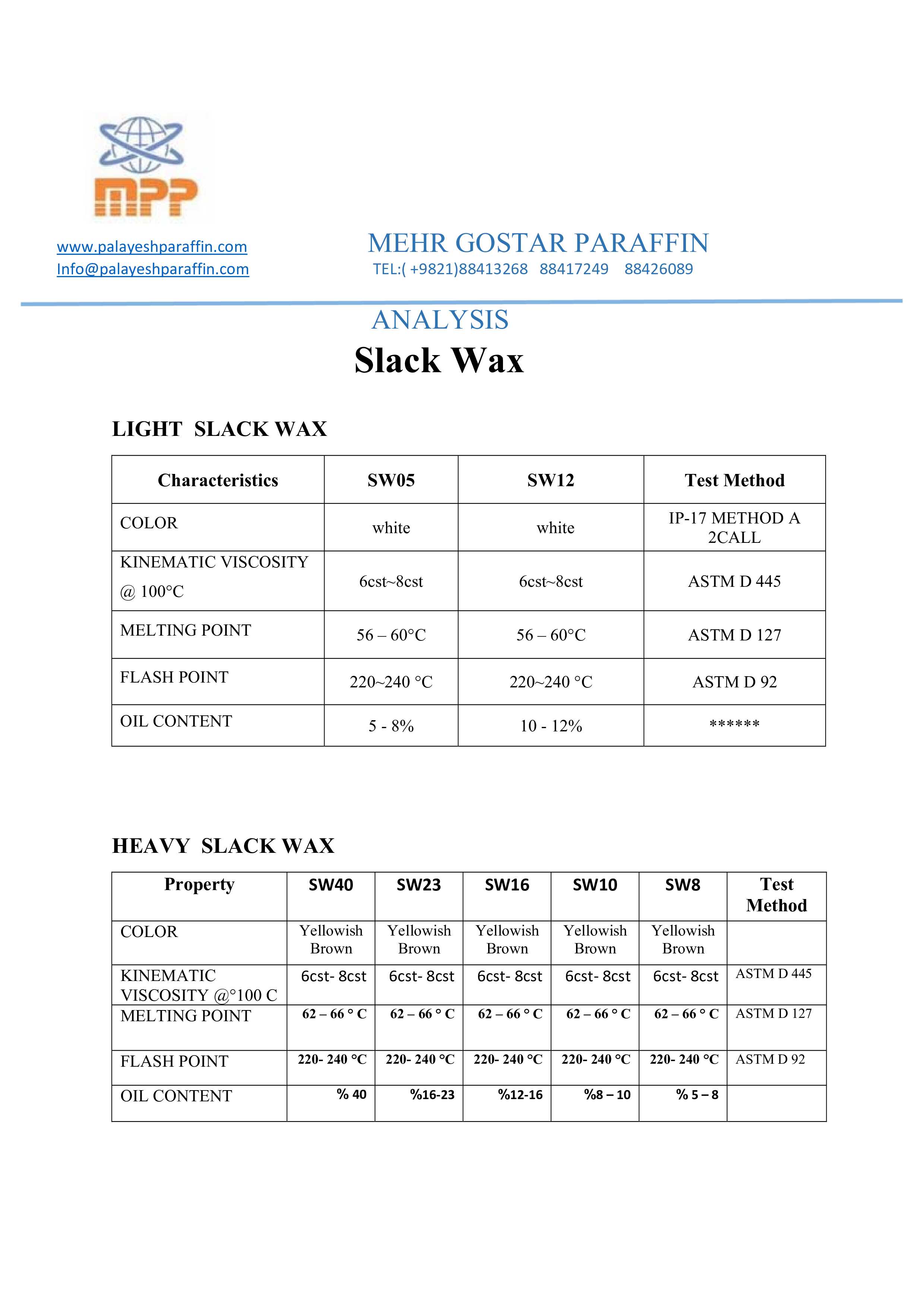

Quality of Slack Wax

The quality of slack wax can vary depending on its source and processing. Generally, high-quality slack wax has the following characteristics:

Low oil content: High-quality slack wax should have a low percentage of oil content. The higher the oil content, the softer the wax will be, which may limit its uses.

- Consistency: Slack wax should have a consistent texture and melting point, making it easier to process and use in various applications.

- Color: High-quality slack wax should have a light, uniform color. Darker wax may indicate the presence of impurities or contaminants.

- Purity: Slack wax should be free from impurities, such as dust, dirt, and other foreign matter.

- Odor: High-quality slack wax should have a neutral odor or a mild, pleasant scent.

Overall, the quality of slack wax is important for determining its suitability for various applications, such as candle-making, packaging, and other industrial uses.

History of Slack Wax

The production of slack wax dates back to the early days of petroleum refining. In the 19th century, petroleum was discovered in various parts of the world, and as the demand for petroleum-based products increased, so did the need for refining processes that could extract useful compounds from crude oil.

During the refining process, crude oil is heated and separated into different fractions based on their boiling points. One of these fractions is the heavy lubricating oil, which is used to make products like motor oil and industrial lubricants. However, this fraction also contains waxy materials that can clog machinery and pipelines.

To remove the waxes, the lubricating oil fraction is chilled, and the waxes are allowed to crystallize and separate from the oil. The resulting material is slack wax, a semi-refined wax with a low melting point and a soft, pliable texture.

Initially, slack wax was considered a waste product and was often discarded. However, as new uses for wax were discovered, such as candle-making, packaging, and cosmetics, slack wax became a valuable commodity. Today, slack wax is further refined and processed to produce fully refined waxes with specific melting points and properties that are used in various applications.

Usages of Slack Wax

Slack wax has a wide range of applications in various industries. Some common uses of slack wax include:

- Candle-making: Slack wax is used in the production of candles, especially those that require a softer wax with a lower melting point.

- Packaging: Slack wax is used in the production of wax-coated paper and cardboard for packaging applications. The wax helps to provide a barrier against moisture and other environmental factors.

- Cosmetics: Slack wax is used in the production of cosmetics and personal care products such as lipsticks, lotions, and creams.

- Polishes: Slack wax is used in the production of polishes for floors, furniture, and automobiles.

- Inks: Slack wax is used in the production of printing inks for newspapers, magazines, and other publications.

- Adhesives: Slack wax is used in the production of adhesives for a variety of applications, including woodworking, construction, and packaging.

- Textile industry: Slack wax is used in the textile industry as a lubricant for weaving machines.

- Rubber industry: Slack wax is used in the rubber industry as a processing aid to improve the handling and processing of rubber compounds.

Overall, slack wax has a diverse range of applications in various industries, and its unique properties make it a valuable raw material for many different products.

Packing of Slack Wax

Slack wax is typically packed in a variety of different ways depending on the requirements of the end-users and the transportation and storage conditions. Some common packaging methods include:

- Bags: Slack wax is often packed in bags made from materials such as kraft paper or woven polypropylene. The bags are available in various sizes, ranging from 20 to 50 kg.

- Cartons: Slack wax can also be packed in cartons, typically made from cardboard. The cartons are available in different sizes and can be used for packing smaller quantities of slack wax.

- Drums: Slack wax can also be packed in steel or plastic drums, typically with a capacity of 180 to 200 kg. The drums are usually lined with a polyethylene bag to prevent leakage.

- ISO tanks: For bulk transportation of slack wax, it can be packed in ISO tanks, which are large tank containers with a capacity of up to 25,000 liters.

- Flexitanks: Slack wax can also be packed in flexitanks, which are large, flexible containers made from polyethylene that can hold up to 24,000 liters of product.

The packaging of slack wax is an important consideration, as it can impact the safety, handling, and transportation of the product. It is essential to follow proper packaging and labeling guidelines to ensure that the product is handled and transported safely and efficiently.